From vroom to volts: NUS students develop Singapore’s first electric race car

The COVID-19 pandemic did not dampen their passion for cars and racing. Although students under the NUS Formula SAE (FSAE) Race Car project could not participate in the annual competition in Michigan since 2020, they remained undaunted. In fact, there is a silver lining to this: the hiatus from the international competition prompted them to try something new – learn to build an electric race car.

The experiential NUS FSAE project under the Engineering Design and Innovation Centre of NUS’ College of Design and Engineering trains students to acquire and apply cutting-edge automotive engineering technologies. Every year, students work together as a team to design and fabricate a Formula-style single seater car to compete in FSAE Michigan, one of the toughest inter-varsity competitions, against some of the best universities around the world.

“The rapidly growing global electric car market has accelerated technological advancements in the sector. It is crucial for our students to be knowledgeable about electric car technologies. Having accumulated rich experience in building internal combustion engine (ICE) cars over the years, we felt it was timely for us to apply our know-how to experiment with building an electric race car and ultimately, empower our students with engineering competencies to help protect the environment in big and small ways,” said Professor Seah Kar Heng, NUS FSAE Project Advisor.

Making the switch comes with challenges, especially since this is the NUS FSAE team’s first foray into electric race cars.

Persevere through challenges

To build the first FSAE electric race car in Singapore, and potentially the region, the NUS team had little reference resources to optimise their systems. “Many of our simulations and tests had to be created from scratch. As we did not have experience with high voltage (HV) systems and EV technologies, we approached companies in the local industry to conduct workshops for us, and also self-study under the guidance of NUS teaching staff, to learn how to handle electrical systems and HV components,” said R22e team member and Year 4 Mechanical Engineering student Muhammad Nazirul Syahmi.

The NUS team also had to familiarise themselves with the rules and regulations in the EV competition. To meet the requirements of the new rules, they had to make drastic design changes to many car components and ensure that the different components worked seamlessly together.

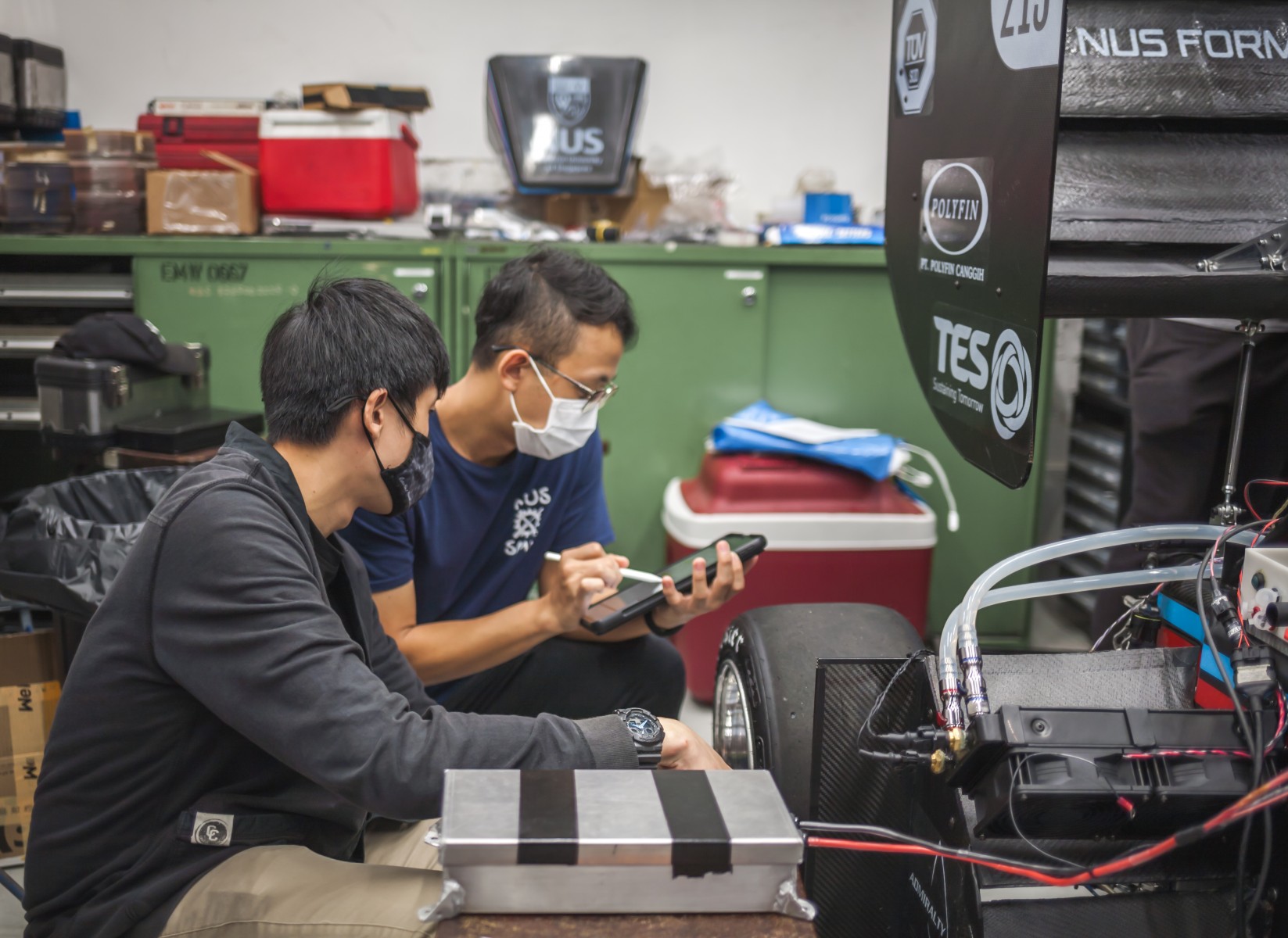

The delays and restrictions caused by the pandemic also severely hampered the team’s manufacturing and assembly phases. To work around these constraints, the students took reference from industry practices and scheduled separate shifts and work hours for different “departments” to work on the car at different times. Priority was also given to the departments that needed more time to work on the car.

“The students were determined to complete the car despite all the challenges they were facing. Their unwavering spirit is truly commendable. Besides applying their engineering knowledge and skills, they have also demonstrated qualities such as teamwork, perseverance and resilience in the course of the project,” said Prof Seah.

Bringing hard work to fruition

After 18 months of hard work, the NUS team of 26 students successfully completed their first electric race car – called R22e - which has features that surpass its ICE predecessors. These features include a motor power of 80 kilowatts, an acceleration of 0 to 100km per hour in 3.9 seconds, a maximum speed of 125.4km per hour and a peak torque of 230Nm.

Putting their invention to the test, the NUS FSAE team submitted the R22e to compete in some of the static events at FSAE Michigan this year, such as the presentation and cost events. The presentation event evaluates the team’s ability to develop and deliver a comprehensive business, logistical production while the objective of the cost event is to evaluate the team’s budget considerations and their ability to incorporate production considerations for production and efficiency.

“While this year’s NUS FSAE project has proven to be more challenging, we are very excited to complete our very first electric Formula SAE race car. This would not have been possible without the steadfast dedication of the entire R22e team, as well as the support and guidance of our mentors, Prof Seah who is our project advisor, and sponsors,” said R22e team member and Year 4 Mechanical Engineering student Mitchel Teo Zhi Kiat. “We plan to improve on this year’s electric race car design, and have it ready for next year’s international FSAE competition in Michigan, US.”

Introducing R22e

The R22e was unveiled by Mr Chee Hong Tat, Senior Minister of State, Ministry of Finance and Ministry of Transport, at an appreciation event for sponsors held on 28 June. Mr Chee first met the NUS Formula SAE team in 2019, where the students showed him how the team had designed and built scaled version of race cars to compete in the annual Formula SAE International Varsity Competition.

At the event, Mr Chee congratulated the NUS team for building Singapore’s first-ever electric Formula SAE race car, and noted that the team had demonstrated resilience in the face of the challenges posed by the COVID-19 pandemic. He added that the launch of the electric race car was timely, and mirrors Singapore’s own effort to electrify our vehicle population.

NUS FSAE Race Car project

Since the inauguration of the NUS FSAE race car project in 2001, a total of 19 ICE cars had been assembled, of which 16 participated in the FSAE Michigan competition. The teams’ capability is evident in the awards and accolades they have achieved over the years, including Chief Design Judge Award and the 3-View Drawing Design Excellence Award in 2021, a 7th overall placement in 2015, coming in 3rd in the static events in 2021, and being the top team in Asia since 2012.